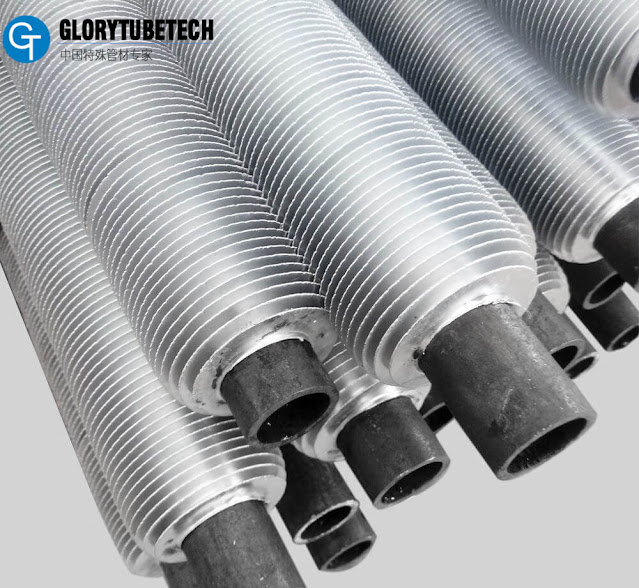

The processing technology of the steel-aluminum cold-rolled finned tube is that the aluminum tube and the steel tube are first processed into a bimetallic composite tube, and then the fin is formed after mechanical cold rolling.

Utilizing the physical properties of the aluminum tube, a fin tube in which the tube with the steel tube as the core is tightly combined with the cold-rolled aluminum fin is made. It is widely used in steel, petroleum, chemical, machinery, shipbuilding, power station, hospital, and food industries.

Study on Cooling Method of SUP9 Spring Flat Steel Hot rolled spring flat steel bar is mainly used for the automotive industry, and it’s the raw material for automobile leaf spring manufacturing. The main varieties of spring steel include 60Si2Mn spring steel, SUP9 spring steel flat bar , 55SiMnVB spring steel. SUP9 spring steel flat bar is produced in accordance with the Japanese standard. At present, many leaf spring manufacturers mostly use SUP9 spring steel as the raw material for manufacturing automotive leaf springs. Compared with 60Si2Mn, SUP9 spring steel has good hardenability and low decarburization tendency, so the mechanical properties and fatigue properties of the leaf springs produced with SUP9 spring steel are better than that of 60Si2Mn steel. However, due to the good hardenability of SUP9 steel , the hardness is often too high during actual rolling production and cooling. The reheating, quenching and tempering treatment are carried out in...

Comments

Post a Comment